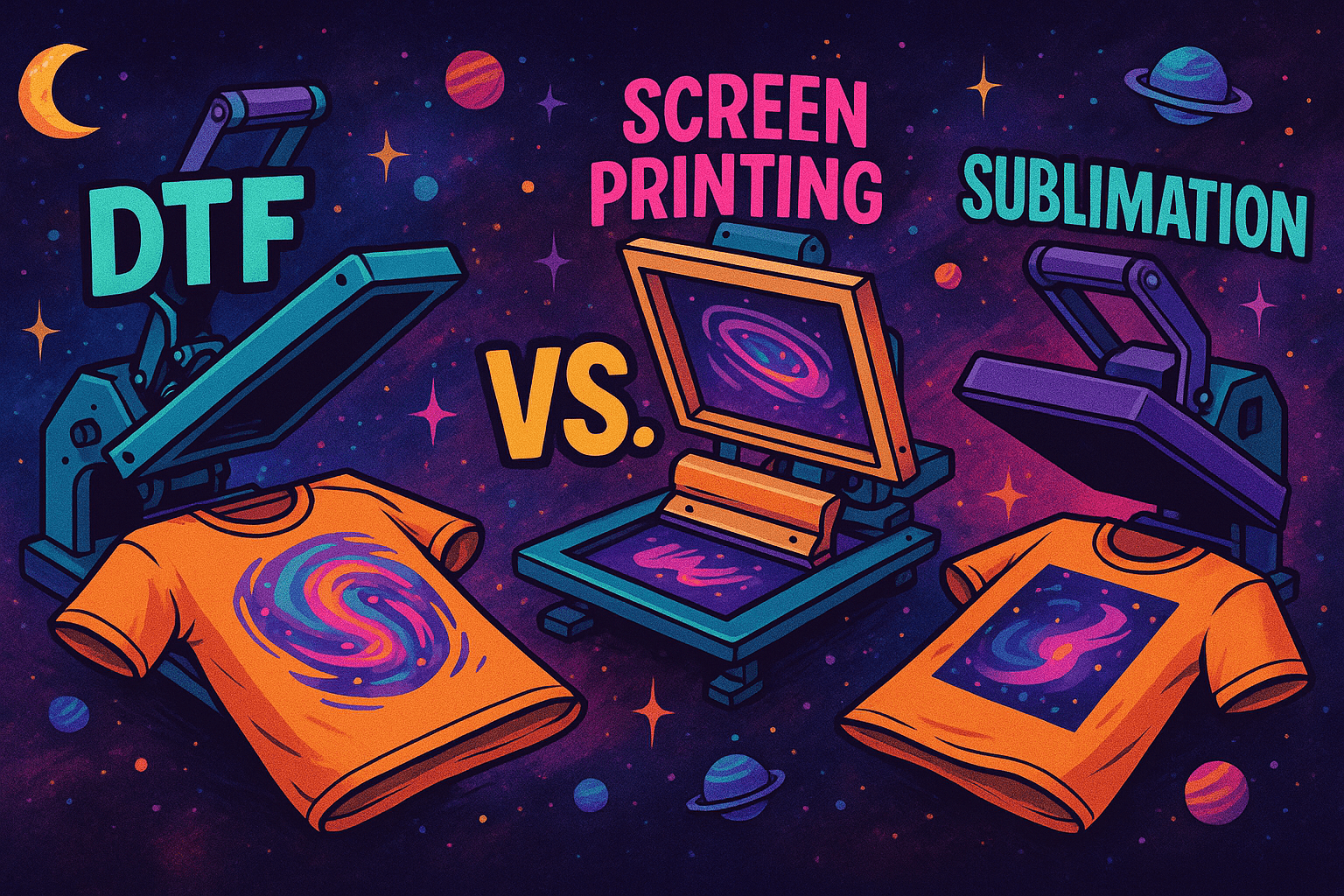

When it comes to customizing apparel, there are many options—DTF transfers, screen printing, and sublimation are among the most popular. But which one is right for you? Whether you’re a small business, a crafter, or managing bulk orders, this guide will break down the pros, cons, and real costs of each method.

✅ What Is DTF Printing?

DTF (Direct to Film) is the newest and fastest-growing method in the print industry. Designs are printed directly onto film, coated in adhesive powder, cured, and then heat-pressed onto fabric.

Pros:

-

Works on nearly any fabric (cotton, polyester, blends, canvas, nylon)

-

Full color with gradients, fine details, and photo-quality prints

-

Stretchable, durable, and soft feel (50+ washes)

-

No minimums—perfect for small runs or test orders

-

Gang sheets save money by combining multiple designs

Cons:

-

Requires a professional heat press for best results

-

Not as “matte” as screen printing (slightly glossy finish)

🎨 What Is Screen Printing?

Screen printing is one of the oldest and most trusted methods in apparel printing. It uses stencils (screens) and ink pushed through mesh to print directly onto garments.

Pros:

-

Extremely durable and long-lasting

-

Vibrant solid colors, bold and classic look

-

Great for large orders of the same design

Cons:

-

Expensive setup (new screen for each color)

-

Limited detail for small text or gradients

-

Not cost-effective for small runs

🌈 What Is Sublimation?

Sublimation printing uses heat to turn ink into gas, bonding it directly into polyester fibers. It’s popular for sports jerseys and all-over prints.

Pros:

-

Vivid, permanent colors that never crack or peel

-

Great for polyester fabrics and white/light garments

-

Perfect for “all-over” designs

Cons:

-

Only works on polyester (or poly-coated products like mugs)

-

Doesn’t work well on dark fabrics

-

Limited to specific blanks

🆚 Side-by-Side Comparison

| Feature | DTF Transfers | Screen Printing | Sublimation |

|---|---|---|---|

| Fabrics | Cotton, poly, blends, nylon, canvas | Best on cotton | Polyester only |

| Colors | Full-color, gradients, detail | Bold solids | Vivid on light poly |

| Durability | 50+ washes | 100+ washes | Permanent |

| Setup Costs | Low / none | High | Medium |

| Best For | Small–medium runs, custom designs | Bulk orders of same design | Sportswear, poly blanks |

💡 Which One Should You Choose?

-

Choose DTF Transfers if you want flexibility, full color, and no minimums. Great for small businesses, creators, and anyone wanting professional results without bulk commitments.

-

Choose Screen Printing if you’re producing hundreds of the same design and want a bold, classic finish.

-

Choose Sublimation if you’re printing all-over designs on polyester (jerseys, uniforms, mugs, and specialty blanks).

🚀 Why Most Businesses Are Switching to DTF

With fast turnaround, no minimums, and full-color printing on almost any fabric, DTF has quickly become the go-to method for apparel decorators. At Smith Artist Productions, we offer:

-

SAP Prime™ Transfers (standard DTF)

-

SAP Spark™ Glitter Transfers (shimmer effect)

-

SAP Raised™ UV Transfers (premium 3D texture)

-

Pro Membership Discounts (biggest savings for repeat buyers)

👉 Order DTF Transfers Today and experience why we’re the fastest-growing DTF shop in the Northwest.